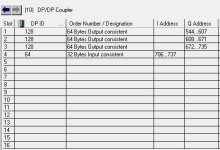

Right so I have an 315-2DP connected to a DP/DP Coupler on port 2 (158-0AD01-0XA0) just sending 8 Bytes out (only works with consistancy over 'total length'). No errors or error LED's appear and everything seems happy only for the Actual Value in the Datablock not being the same as the initial value despite no changes being implemented?

On the other port (1)of the DP is a DeltaV DCS, this is set to pick up the 8 Bytes, when this profibus is cable is connected into the DP Coupler it goes crazy, SF1, SF2, & BF2 Flash and BF1 is always solid regardless. Wiring isn't an issues here though as both sides can see eachother in diagnostics. I then get the error code 32928 on the S7 side saying an error occured accessing data.

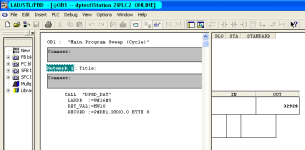

S7 images attached

I'm not too sure where my mistake is here? Any suggestions? Thanks!

On the other port (1)of the DP is a DeltaV DCS, this is set to pick up the 8 Bytes, when this profibus is cable is connected into the DP Coupler it goes crazy, SF1, SF2, & BF2 Flash and BF1 is always solid regardless. Wiring isn't an issues here though as both sides can see eachother in diagnostics. I then get the error code 32928 on the S7 side saying an error occured accessing data.

S7 images attached

I'm not too sure where my mistake is here? Any suggestions? Thanks!